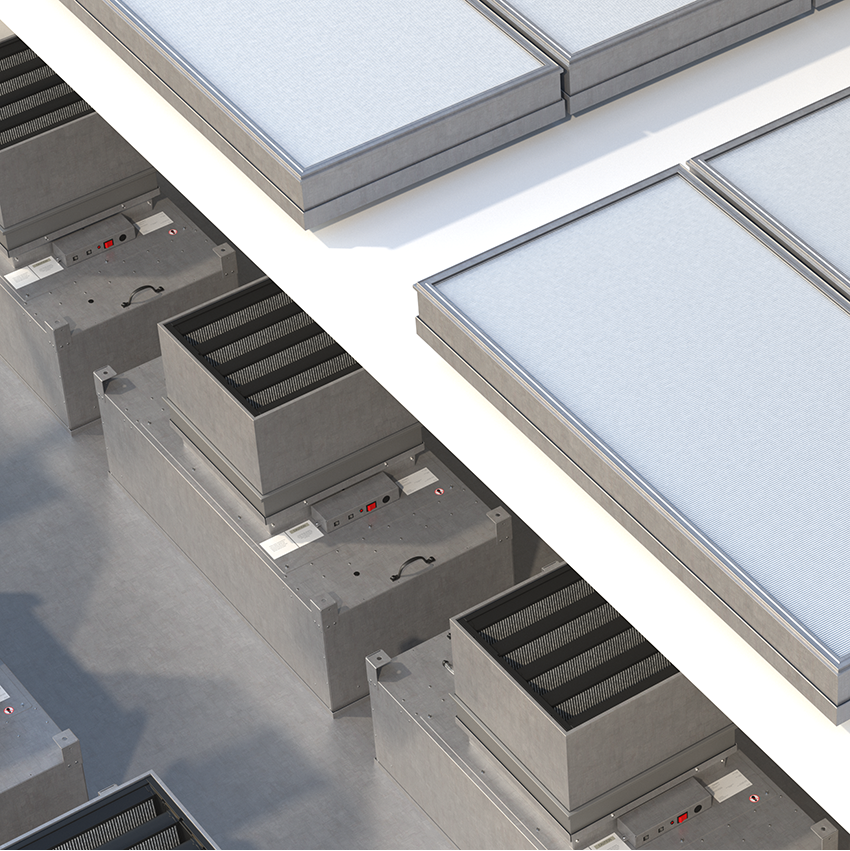

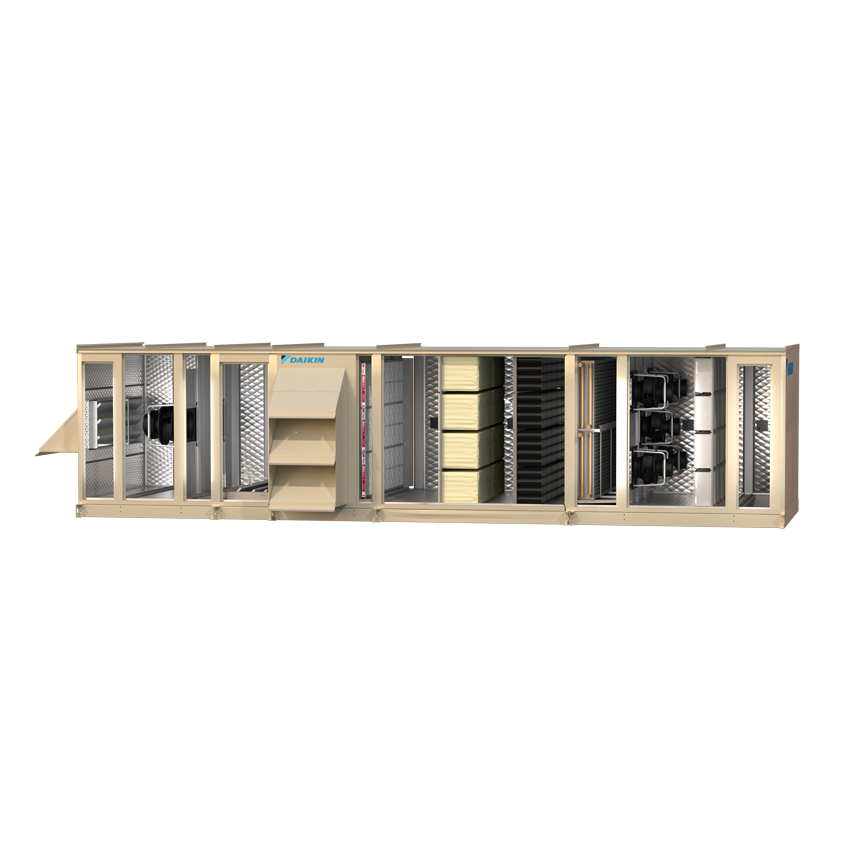

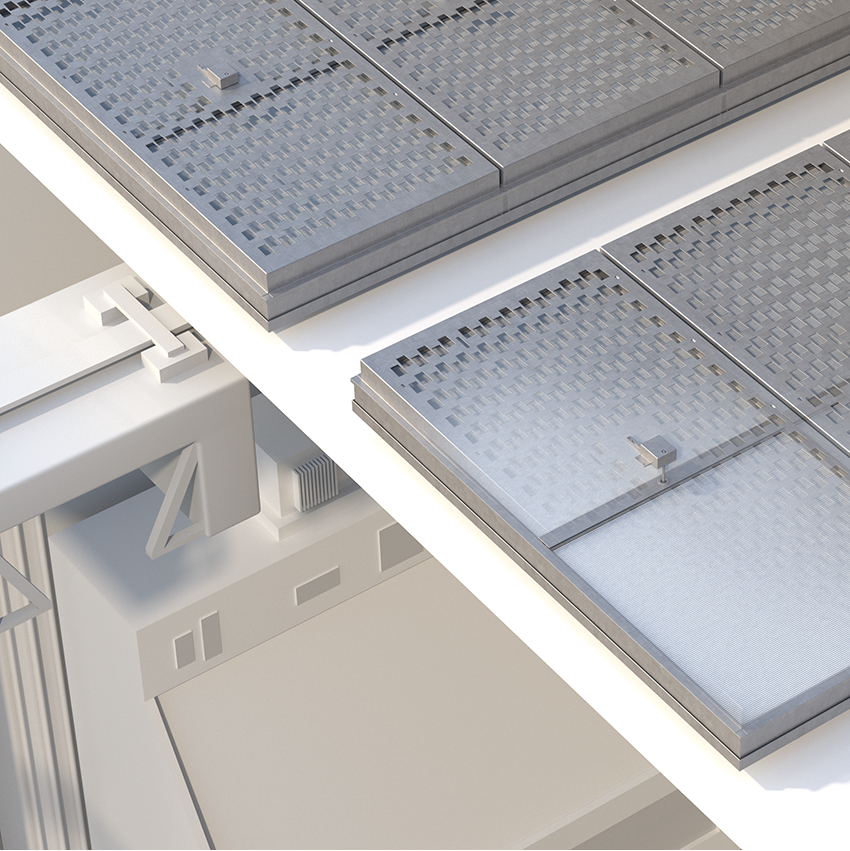

Combining high-quality prefilters and HEPA filters is recommended to help control the spread of AMC in cleanrooms. Highly efficient AstroSorb filters remove all classes of AMC from cleanroom air.

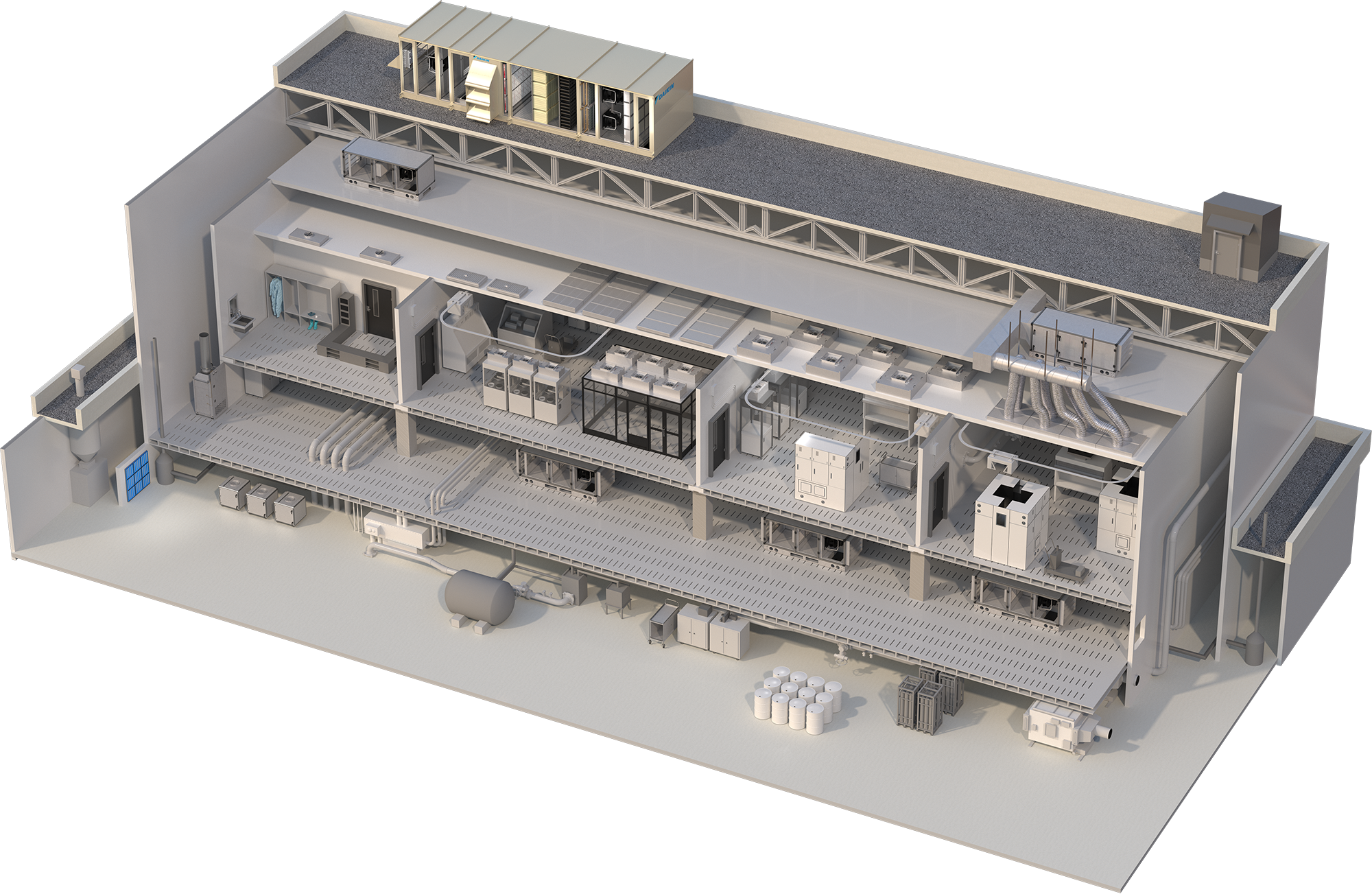

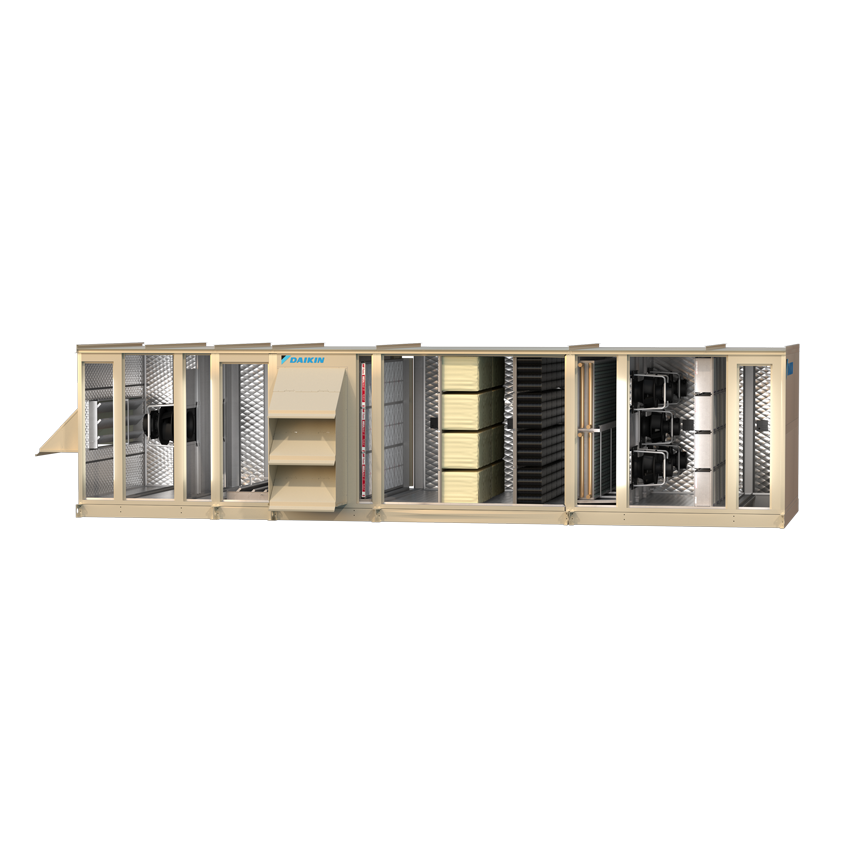

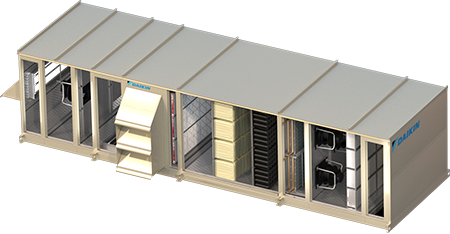

Technology and control at the molecular level is critical to success. We design the clean air innovation needed to help you take more command over the production environment. Boron-free and chemically inert filter media limit off-gassing that can damage microelectronics. Long-lasting, high-efficiency HEPA filtration systems provide critical control of particulates and can help reduce energy use and labor costs. Highly effective filtration solutions control airborne molecular contamination (AMC) in critical process areas. AAF offers the clean air solutions and insights needed to help keep the microelectronics industry moving forward.

Combining high-quality prefilters and HEPA filters is recommended to help control the spread of AMC in cleanrooms. Highly efficient AstroSorb filters remove all classes of AMC from cleanroom air.

Look for boron-free filters to avoid off-gassing that can damage microelectronic circuit boards and lead to intermittent and hard failures.

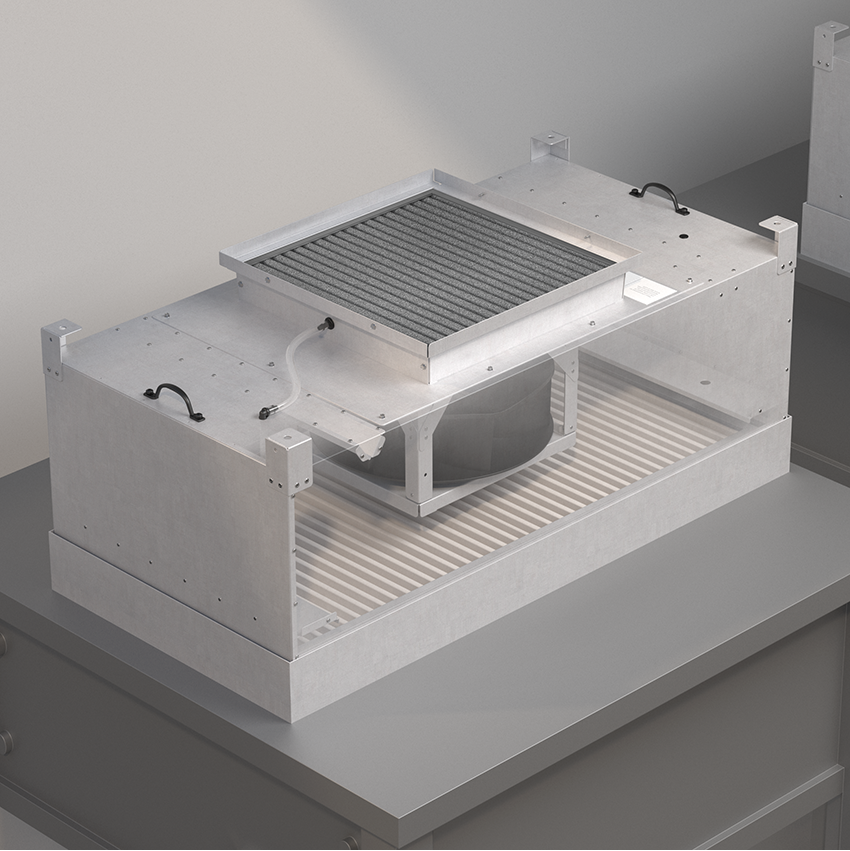

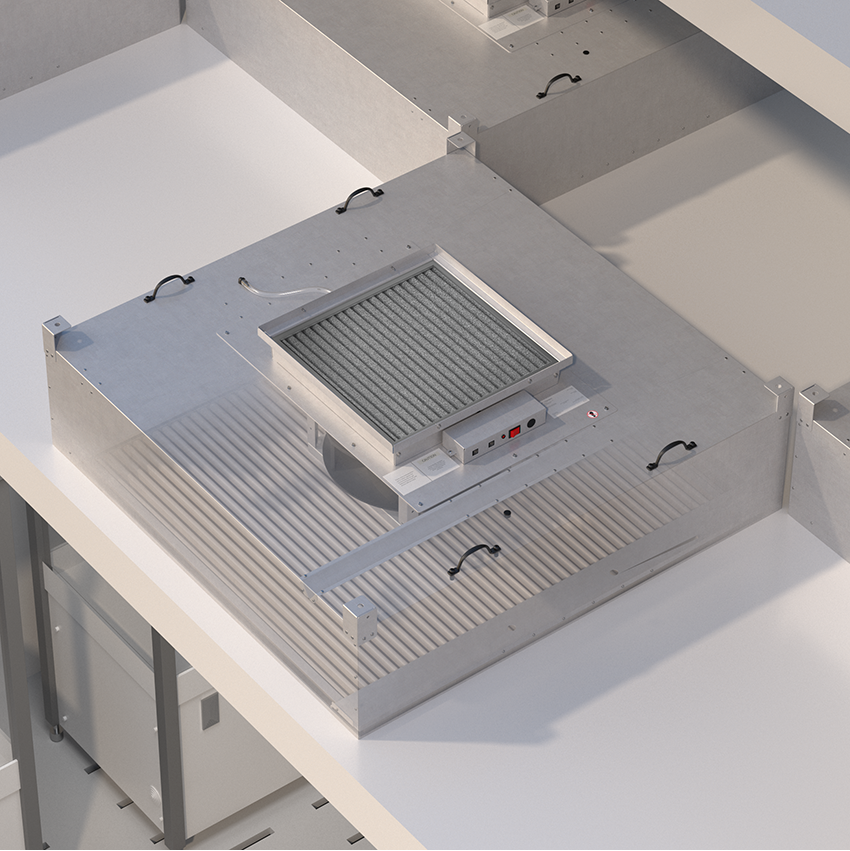

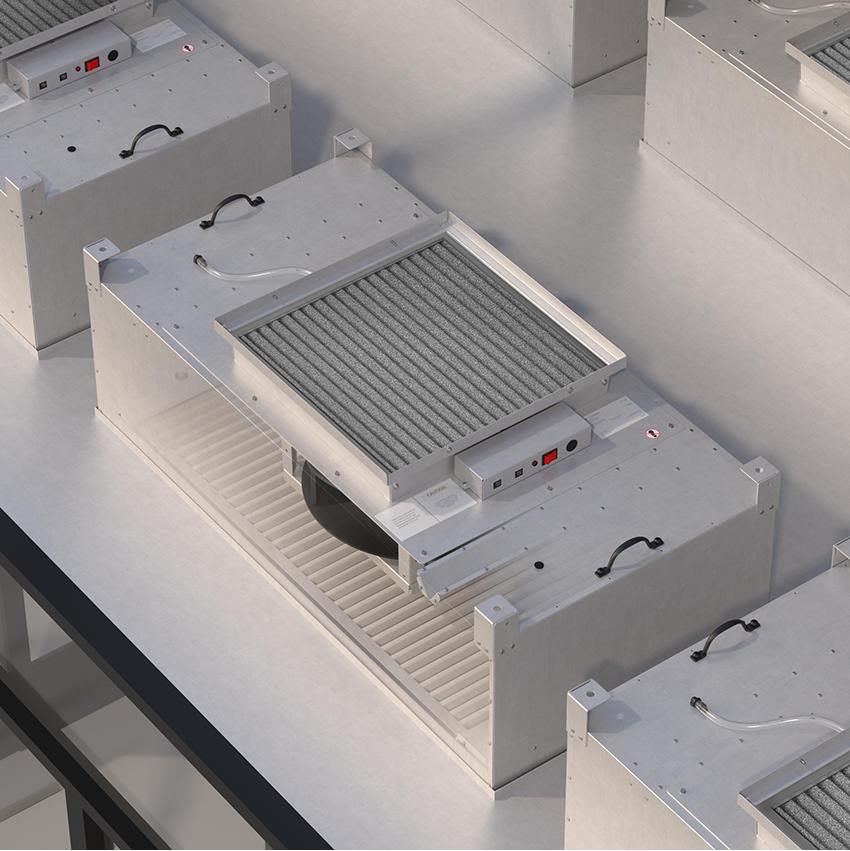

Polymer-based filter media such as AAF’s eFRM and ePTFE offer more tensile strength and abrasion resistance than traditional glass filters.

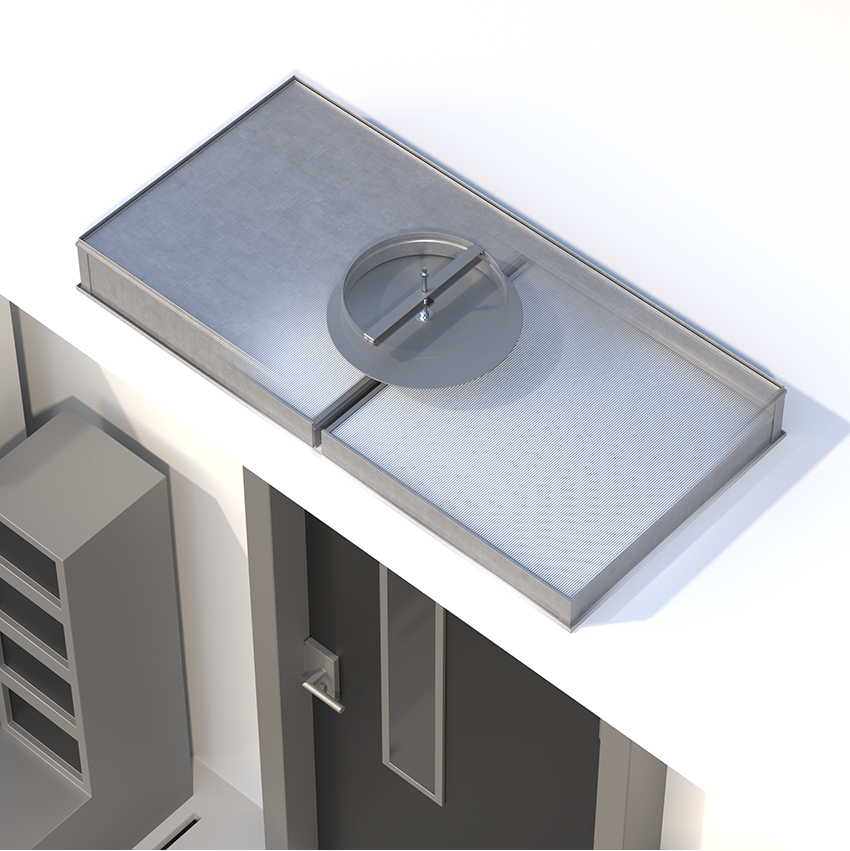

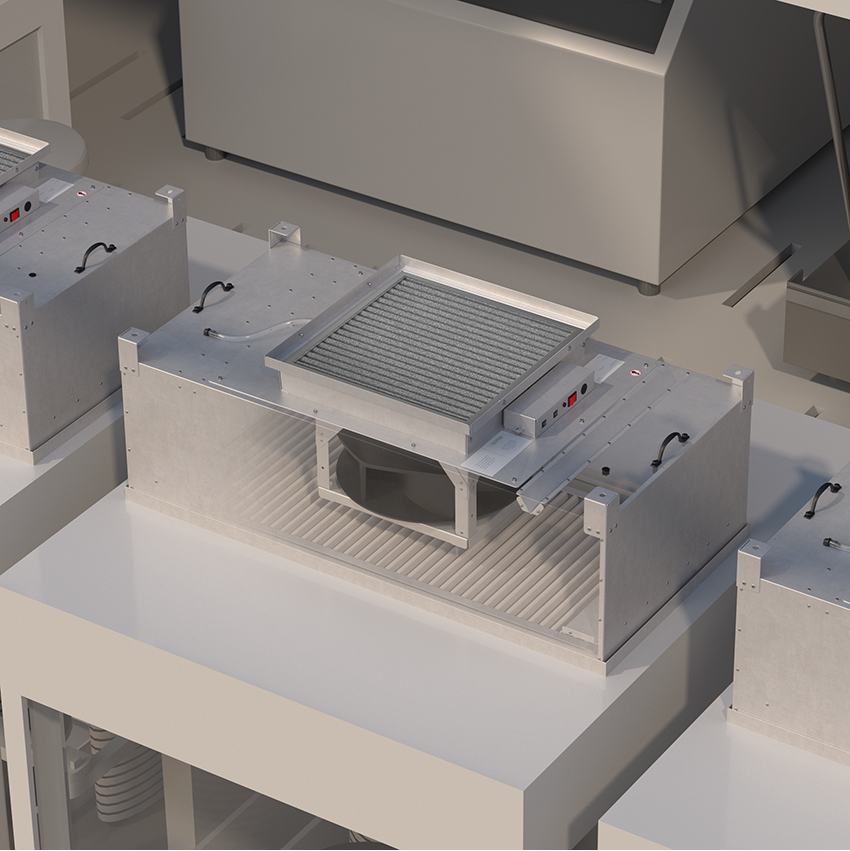

Unlike V-bank HEPA filters, MEGAcel l filters can be scanned for potential leaks.

AAF’s alternatives to standard filter media offer advantages for the cleanroom environment. These advanced media are boron-free, so they won’t release boron gas that can cause a film on wafers. Filters like the MEGAcel l eFRM and MEGAcel ll ePTFE are also chemically inert and hydrophobic, helping make them resistant to water and chemicals in the airstream. Their durability can minimize damage during the handling and installation process.

Unlike V-bank HEPA filters, MEGAcel l filters can be scanned for potential leaks. They’re also more durable than traditional glass filters, so they can hold up to normal shipping, storage and installation. Their rugged design not only helps protect against leaks, but it can also help reduce the inventory needed for filter changeouts.

Learn how AAF can make a difference.